1.JINCHENG have more than 20 years history for R&D and production of serious filtration equipments,we are not only have strong technical support but also own advanced processing equipments,which enable us to product the large and medium-sized machine;

2.All raw materials come from well-known manufacturers to ensure the stability and service life of the equipment in the later stage.The quotation is very competitive in the market

3.JINCHENG Filter Press are deigned to generate easily managed dry product or waste material, the filter press also provides tha ability to optimize the recovery of clean,resuable water.

4.JINCHENG Filter Press can equip with different funcitons to meet customer rquirements, for example, quick-open system, shaking device,self-washing system and so on. we will design and help to build a whole production line;

5.JINCHENG Customer Service Team offers a wide range of fast spare parts sourcing as well as routine and emergency maintenance service support. All 6.JINCHENG Filter Presses can have customer remote control access capability for efficient monitoring and troubleshooting

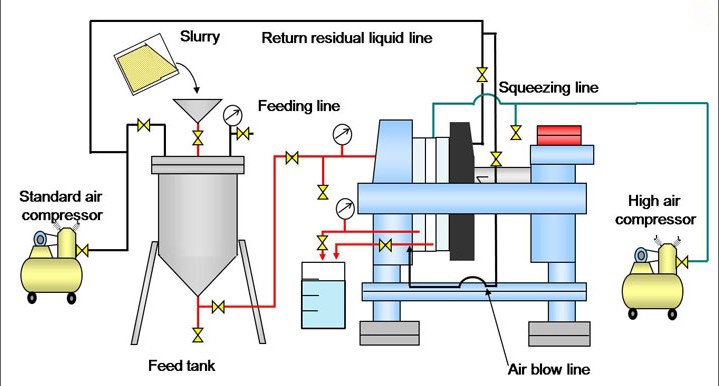

The membrane filter press or diaphragm filter press is composedof membrane plate and chamber plate, which are arranged to form a filter chamber.Under the pressure of feeding pump,the slurry will feeding into the filter chamber, and the solid and liquids are separated through the filter medium(filter cloth).After the solid forms cake,air or high pressure water will send into inner layer of diamphram to fully press the middle cake, reduce more water content and facilitate the removal.For the filtration of viscous materials and high requirements to the final water content,the membrane filter press is a good choice.

Model | Filtering | Plate | Chamber | Cake | Plate |

XMG/870-30U | 50 | 870*870 | 745 | 30 | 18/19 |

60 | 900 | 22/23 | |||

70 | 1053 | 26/27 | |||

80 | 1170 | 29/30 | |||

XMG/1000-30U | 80 | 1000*1000 | 1175 | 22/23 | |

90 | 1330 | 25/26 | |||

100 | 1480 | 28/29 | |||

770 | 1635 | 31/32 | |||

120 | 1785 | 34/35 | |||

XMG/1250-30U | 120 | 1250*1250 | 1785 | 30 | 21/22 |

140 | 2110 | 25/26 | |||

150 | 2270 | 27/28 | |||

160 | 2430 | 39/30 | |||

180 | 2760 | 33/34 | |||

200 | 3000 | 36/37 | |||

250 | 3810 | 46/47 |

Welcome to visit our website. If you need an olive oil production line, please write down any questions, we will reply as soon as possible.