1.JINCHENG Filter Press are deigned to generate easily managed dry product or waste material, the filter press also provides tha ability to optimize the recovery of clean,resuable water.

2.JINCHENG Filter Press can equip with different funcitons to meet customer rquirements, for example, quick-open system, shaking device,self-washing system and so on. we will design and help to build a whole production line;

3.JINCHENG Customer Service Team offers a wide range of fast spare parts sourcing as well as routine and emergency maintenance service support.

4.JINCHENG Filter Presses can have customer remote control access capability for efficient monitoring and troubleshooting;

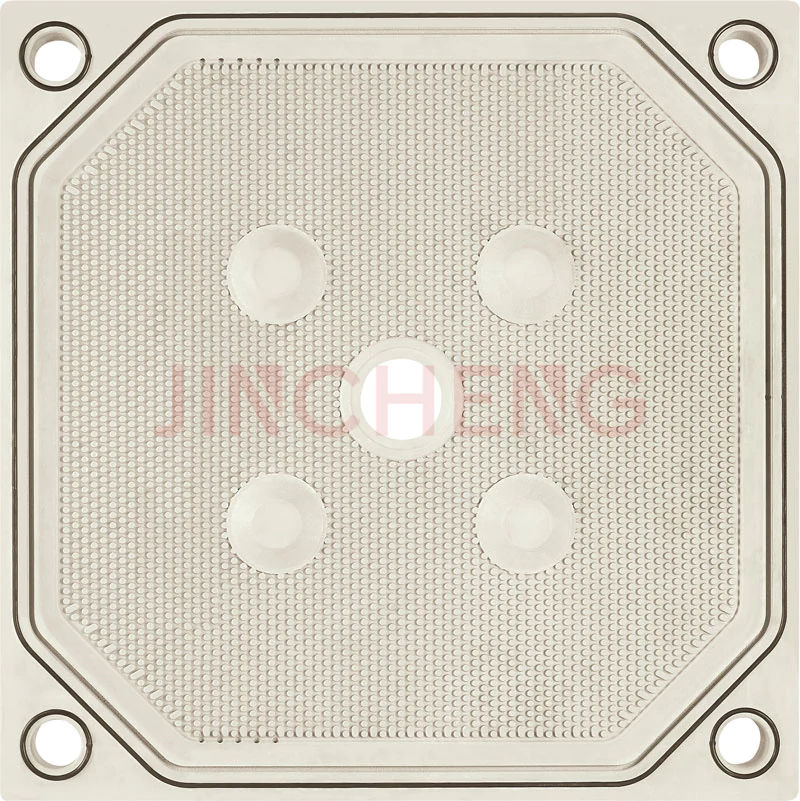

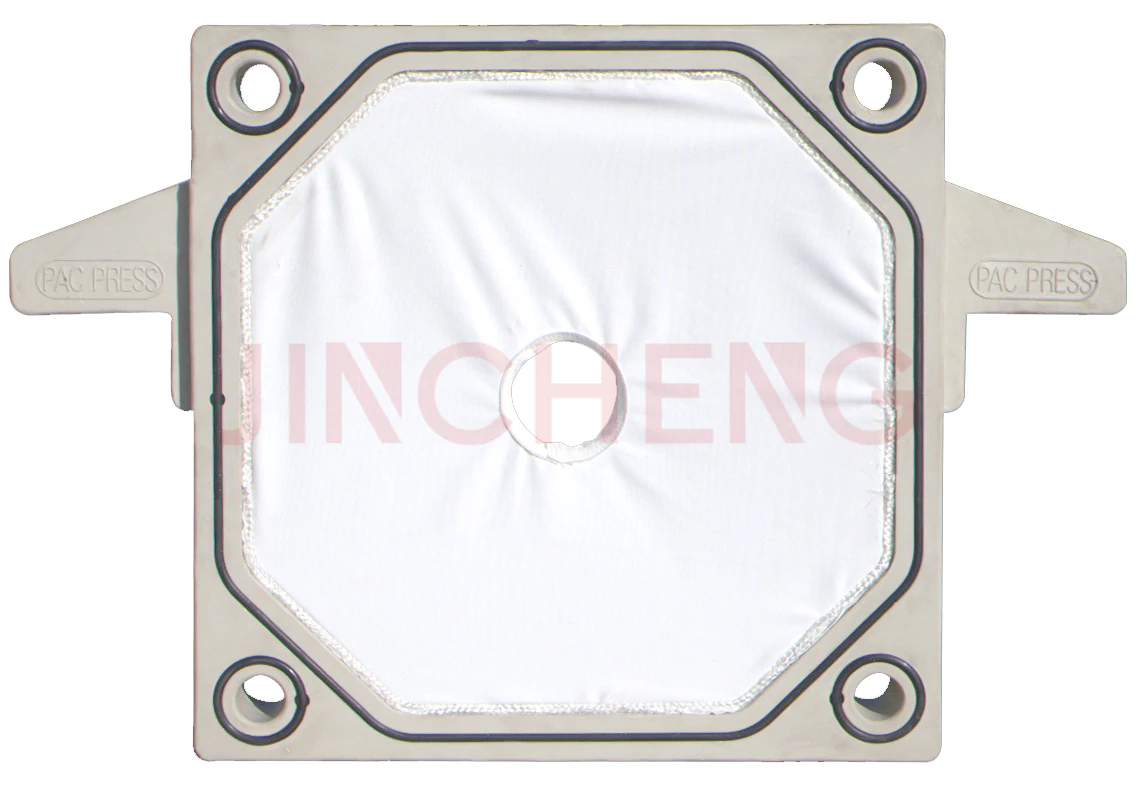

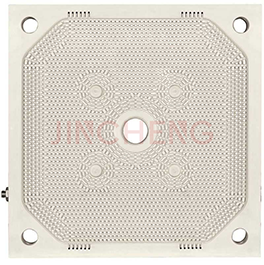

Chamber filter plate is a modification of filter plate and frame. Two compacted plates create an individual chamber; filter cake produces on the plates in layer form. As the thickness of the cake increases, the permeability and flow rate decreases causing longer filtration cycles and higher operation costs.During the later stage of filter cycle, high feed pressure is employed to dry the filter cake and this dewatering period is quite long. This period is usually called non-productive phase.

Name | Model | Size | Raw material |

Chamber filter plate | 390 | 390*390mm | High reinforced PP |

Chamber filter plate | 520 | 520*520mm | High reinforced PP |

Chamber filter plate | 800 | 800*800mm | High reinforced PP |

Chamber filter plate | 1000 | 1000*1000mm | High reinforced PP |

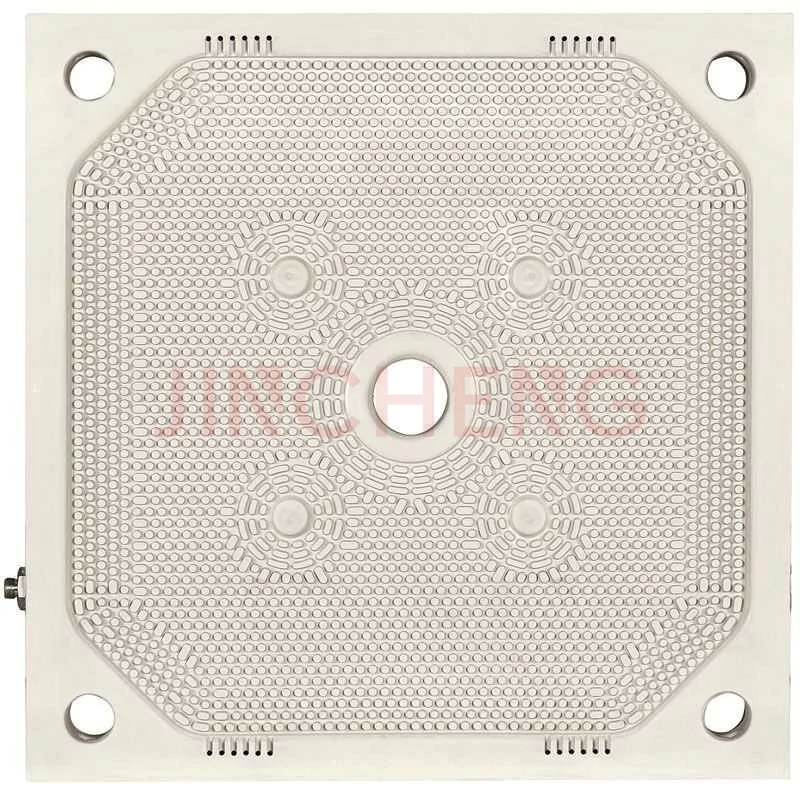

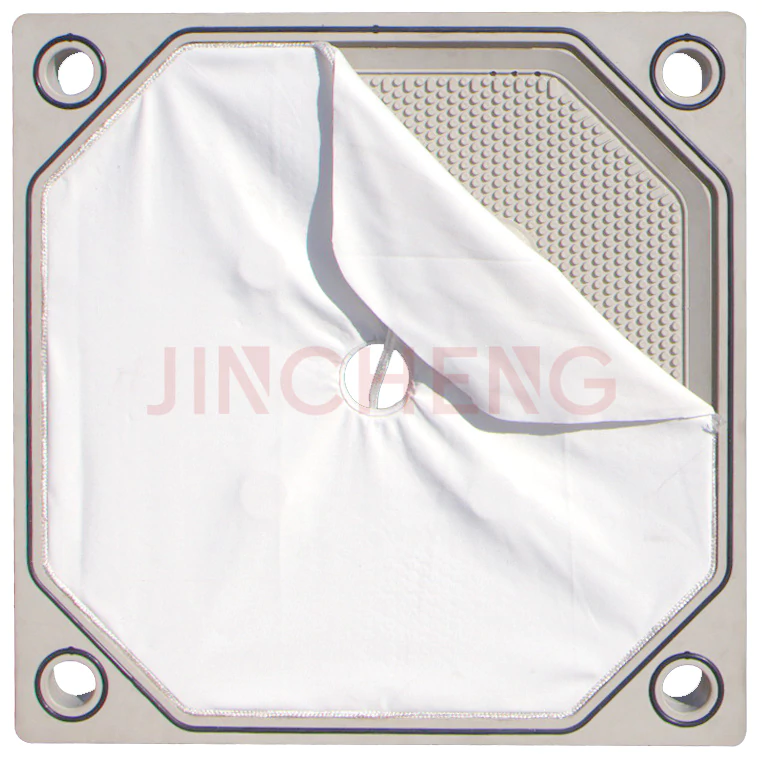

Membrane filter plate | 870 | 870*870mm | High reinforced PP |

Membrane filter plate | 1000 | 1000*1000mm | High reinforced PP |

Membrane filter plate | 1250 | 1250*1250mm | High reinforced PP |

Membrane filter plate | 1500 | 1500*1500mm | High reinforced PP |

Welcome to visit our website. If you need an olive oil production line, please write down any questions, we will reply as soon as possible.